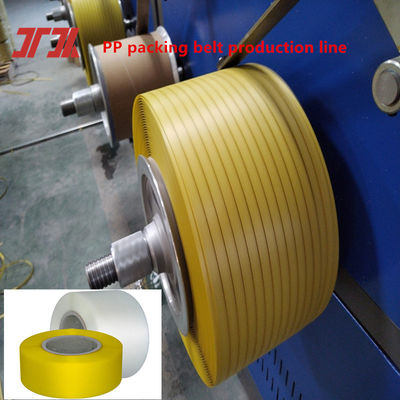

Máquina automática de fabricación de flejes de PP con bobinadora de 5-19 mm, línea de producción de flejes de plástico con PLC

Somos el fabricante profesional de máquinas para fabricar flejes de PP PET y flejes de PP PET con casi 30 años de experiencia. Primero, veamos:

¿Cómo elegir: flejes de PP vs. PET?

Utilice este sencillo diagrama de flujo de decisiones:

1. ¿Es la carga pesada, densa o rígida?

2. ¿Es la carga propensa a asentarse, comprimirse o encogerse? (por ejemplo, balas comprimidas, madera, materiales porosos)

3. ¿Estará el paquete expuesto a almacenamiento al aire libre, cambios amplios de temperatura o humedad?

4. ¿Es el costo el factor más importante?

-

Sí → Elija PP. Ofrece un rendimiento adecuado para muchas tareas ligeras al precio más bajo.

-

No → Reevalúe en función de las preguntas anteriores; PET a menudo proporciona un mejor valor a largo plazo para aplicaciones críticas.

Flujo del proceso de la línea de producción de flejes de embalaje de PP

①Material→②Mezcla de materia prima→③Secado por precristalización→④Extrusión→⑤Enfriamiento→⑥Precalentamiento en horno→⑦Estiramiento primario→⑧Estiramiento secundario→⑨Estampado→⑩Formación en caliente→⑪Enfriamiento→⑫Bobinado (producto terminado)

Especificación de la máquina para fabricar flejes de PP JIATUO

| Modelo |

Salida |

Cantidad de flejes |

Ancho del fleje |

Materia prima |

| JT-PP90 |

100-120 kg/h |

2 flejes |

5-19 mm |

100% material reciclado de PP

& nueva materia prima

|

| JT-PP110 |

230-260 kg/h |

4 flejes |

5-19 mm |

| JT-PP125 |

350-380 kg/h |

6 flejes |

5-19 mm |

Característica de la línea de producción de flejes de PP

El diseño y la configuración de la máquina controlan directamente la calidad del producto final de flejado de PP:

Dimensiones consistentes:El control preciso sobre la matriz y el proceso de estiramiento garantiza que el ancho y el grosor del fleje sean uniformes en todo el rollo.

Alta resistencia a la tracción:Se logra mediante el control preciso del proceso de orientación (estiramiento).

Buen acabado superficial:Una máquina calibrada correctamente produce un fleje con una superficie lisa y cerosa que se alimenta fácilmente a través de las herramientas de flejado.

Alargamiento controlado:Los procesos de estiramiento y fijación térmica determinan el alargamiento a la rotura del fleje, una característica clave de rendimiento.

Excelente bobinado de bobinas:Produce rollos apretados, limpios y estables que son fáciles de manejar, enviar y cargar en máquinas de flejado automáticas.

Servicio JIATUO

Servicios de preventa

-

Soporte en línea 24/7: Brindamos asistencia las 24 horas del día, los 7 días de la semana. Reciba respuestas rápidas por correo electrónico o conéctese con nosotros instantáneamente a través de su aplicación de mensajería preferida (WhatsApp, WeChat, etc.) para discutir todas sus consultas.

-

Consulta experta: Ofrecemos presentaciones de productos profesionales y pacientes, y estamos listos para compartir fotos detalladas y videos de trabajo para brindarle una comprensión integral de nuestras máquinas.

Servicios de venta

-

Control de calidad riguroso: Cada máquina se somete a pruebas e inspecciones exhaustivas antes del envío.

-

Confirmación y embalaje transparentes: Le enviaremos fotos de su pedido para su confirmación antes de embalarlo de forma segura en una caja de madera de exportación estándar.

Servicios postventa

-

Seguro de envío gratuito: Sus productos están asegurados para una entrega segura.

-

Soporte técnico dedicado: Nuestro equipo en línea 24/7 está listo para resolver cualquier problema. Proporcionamos manuales en inglés, soporte técnico y videos de mantenimiento/instalación. Si es necesario, podemos enviar un ingeniero a su fábrica.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!

Calificación General

Imagen de calificación

La siguiente es la distribución de todas las calificacionesTodas las reseñas