Velocidad de funcionamiento de 250-300 m/min Línea de producción de extrusión de correa de embalaje de PP con remolque automático

Flujo de proceso de la línea de producción de tiras de embalaje de PP

1Material→2Materia prima de estiramiento→3Seca previa a la cristalización→4Extrusión→5Refrigerado→6précalentamiento del horno de estiramiento→7estiramiento→8impresión ((si es necesario)→9Embossing→10horno de moldeado→11Refrigerado→12Enrollamiento ((producto acabado)

Parámetros de las máquinas de producción PP 1 a 2

| 1 |

Materiales |

Peléts de materia prima de polipropileno PP, pellets reciclados. |

| 2 |

Producto |

Correa de PP (1 molde para 2 correas) |

| 3 |

Capacidad |

100 a 120 kg/h |

| 4 |

Potencia instalada total |

80kw, (el consumo de energía real es del 40-50%) |

| 5 |

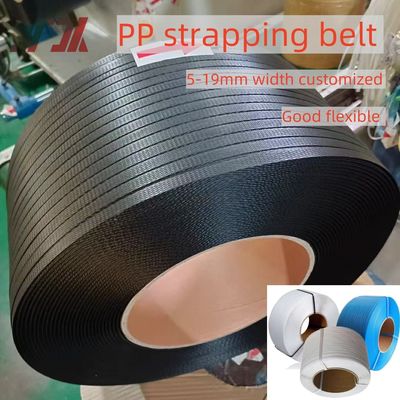

Ancho de la correa |

5 mm a 19 mm |

| 6 |

El grosor |

0.4 mm-1,2 mm |

| 7 |

Trabajo |

2 personas por turno |

| 8 |

Se requiere taller |

El número de unidades de la unidad de ensayo se calculará en función de las características de la unidad de ensayo. |

| 9 |

Fuente de energía |

380 V, 50 Hz, 3 fases (según las necesidades del cliente) |

| 10 |

Componentes eléctricos |

El Sr. Schneider |

| 11 |

Las demás máquinas |

Técnicas de tratamiento de los residuos |

| 12 |

Interruptores |

El Fotek |

| 13 |

Potencia del motor |

- ¿Qué es eso? |

Características de la máquina para hacer correas de PP

1. tornillo especialmente diseñado con relación de compresión optimizada para PP, con un diámetro gradualmente cambiante y ranuras de rosca más profundas en la sección de fusión.

2La caja de cambios endurecida combinada con una matriz ajustable con precisión garantiza una producción estable y una superficie lisa de la correa.

3El recipiente de refrigeración de acero inoxidable tratado con cuatro procesos térmicos sustituye a los diseños convencionales.

4Los rodillos de extracción más grandes garantizan una calidad del producto constante.

5La tecnología de laminación avanzada supera los problemas tradicionales de las molinas, como la alta pendiente y la desviación de la curva.

6Los rodillos de relieve grabados con láser producen patrones claros y uniformes.

7La matriz de extrusión personalizada y el cambio de pantalla mejorado permiten el reemplazo continuo de la pantalla sin fugas de material.

Muestras de productos finales de banda de cinta de PP/línea de extrusión de cinturón/banda de cinta de PP/máquina de extrusión de cinturón

Aplicación de las correas de PP

Preguntas frecuentes:

P: ¿Su empresa es fábrica o empresa comercial?

R: Somos fábrica, estamos involucrados en este negocio desde hace 30 años, también tenemos nuestra propia fábrica de correas de PET.

- ¿ Qué? ¿Cuál es el procedimiento cuando usted compra nuestra máquina?

A: ¿Qué quieres decir?Confirm the technology and machine configure -----confirm price----sign contract and make PI---send down payment - start to make machine---inform you before machine finish-you come our factory to check the machine---you accept the machine ----finish payment-exporting---send our technicians to your factory install the machine---answer your question all the using time and supply spare parts with cost only.

P: ¿Puede garantizar su calidad?

R: Por supuesto. Somos la fábrica de fabricación. Lo más importante, ponemos un alto valor en nuestra reputación. La mejor calidad es nuestro principio todo el tiempo. Puede estar seguro de nuestra producción completamente.

P: ¿Cuál es el plazo de pago?

R: La mejor manera para los dos es el depósito del 30% T/T y el pago del 70% T/T antes del envío, ya que probaremos la máquina antes del envío.Usted puede elegir la forma más conveniente (Términos de pago): T/T, L/C, Western Union, etc.)

Perfil de la empresa:

Shenzhen Jiatuo Plastic Machinery Co., Ltd, especializada en la producción y desarrollo de tiras de PP y PET durante más de 20 años.

Los productos consisten en una máquina para fabricar tiras de PET/PP,Máquina de fabricación de ratán, máquina portátil de cinta, máquina de recubrimiento de plástico, rodillo de relieve de plástico de alta precisión, enrollador de tiras de PP y PET, máquina de prueba de tracción, máquina de impresión de tiras,Cambiador de pantalla de extrusión de plásticoLas partes de las máquinas de extrusión, las máquinas de succión automática, los alimentadores de tornillo, los trituradores, etc.Máquina de embalaje automática para todas las bolsas y máquina de embalaje automática; Máquina de PP de alta calidad, de alta resistencia y respetuosa con el medio ambiente, cinturón de embalaje de PP, cinturón de acero de plástico para mascotas y otros materiales de embalaje.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!

Calificación General

Imagen de calificación

La siguiente es la distribución de todas las calificacionesTodas las reseñas